I units to undertake the four projects in the column for the special-shaped structural support components, up and down 40mm thick flange plate needs bending, due to the thick plate, tight schedule, outsourcing processing has been too late. The decision by the leadership of the company, as the Minister took the lead in the company's original 1000T press on the basis of restructuring, both to solve the equipment idle, but also solve the pressing needs of the pressing components. In the production of upper and lower mold in the process of a lot of innovation, both to ensure product quality, but also improve production efficiency.

Specific production advantages are as follows:

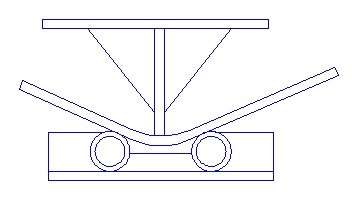

1, the use of thick-walled lower mold support seamless pipe, reducing the weight of abrasive to ensure abrasive rigidity. The member is not a single support distance during the bending process and helps to shape the member.

2, the use of thick plate on the die wide head design, under the pressure to ensure the curvature of the member, a molding, without the need for multi-knife pressure molding.

3, the next two mold spacing strictly calculated by the work, give full consideration to the rebound coefficient of steel, to ensure the bending angle of the component.

New mold design